Occupational accidents not only impair employees’ work capabilities but also affect their morale and sense of identification to the Company. As Taiflex regards employees as the most valuable assets, we are committed to safeguarding their physical and mental health, as well as constructing a safe and conducive work environment.

In view of the fact that several companies in Taiwan had suffered major fires at factories in the past with loss of life or substantial financial losses which adversely affected their sustainable operations; and the causes for such incidents were personnel's unfamiliarity with materials or misunderstanding of proper handling procedures, we have included chemical/toxic substance management as a material topic.

With the core philosophy of “people-oriented,”Taiflex strives to create a“fundamentally safe” work environment, aiming to build the best protection for employee health and safety while strengthening our industry competitiveness. With the ultimate goal of “zero occupational accidents,”We have formulated the following five major OSH policies:

Comply with occupational safety laws and regulations and enhance corporate image.

Unite as a team in communication and cooperation and raise company-wide safety awareness.

Commit to a sound work environment and promote the physical/mental well-being of employees.

Identify occupational hazard risks and create a safe workplace.

Advance occupational safety management performance and achieve the goal of corporate sustainability.

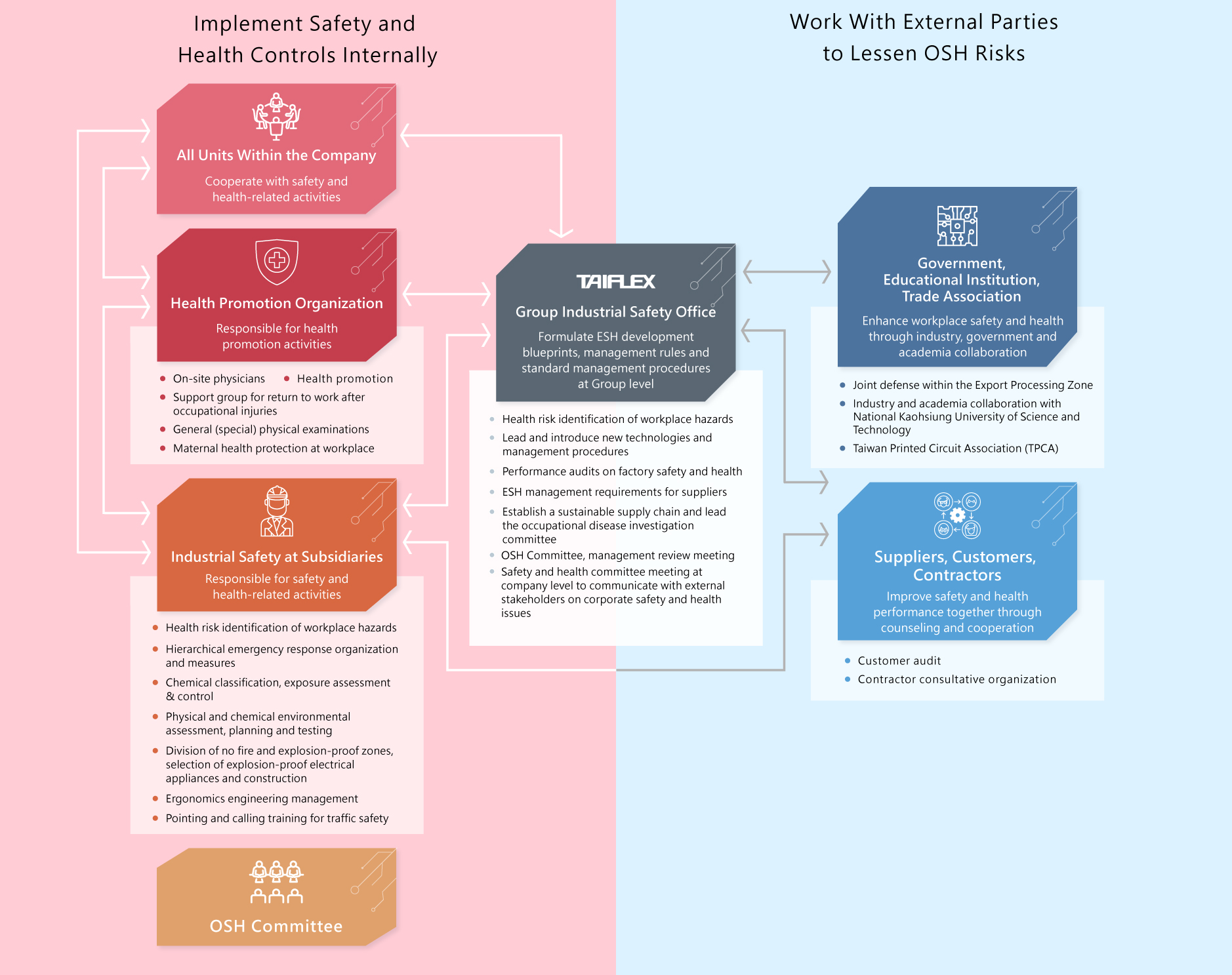

Taiflex has established the Occupational Safety & Health Management Division to coordinate OSH management and planning, and continuously promote the safety culture at Taiflex. On-site safety and health tasks are carried out through cooperation between OSH personnel, the Industrial Safety Section of the Manufacturing Center and the safety and health personnel of each unit.

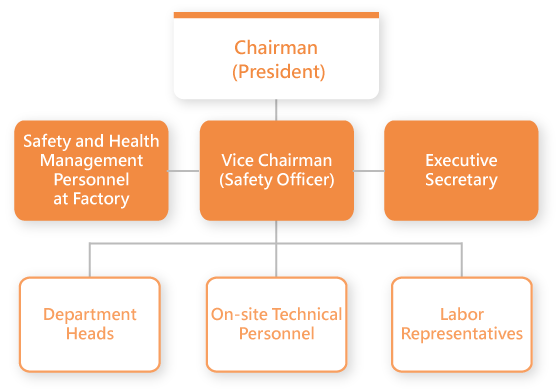

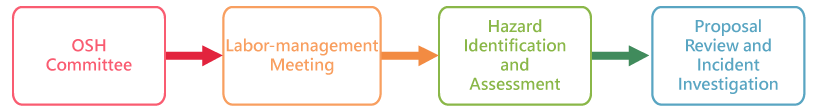

Taiflex's OSH Committee provides a formal channel for the management and employees to communicate face-to-face on OSH issues. Besides quarterly Committee meetings, department heads would hold monthly meetings of the same purpose in response to the growing scale of the Company for OSH management.

| Factory / Personnel | Management Representative | Safety and Health Personnel / Technical Personnel | Labor Representative |

|---|---|---|---|

| Taiflex 1 | 1 | 1 | 1 |

| Taiflex 2 | 2 | 3 | 4 |

| Taiflex 3 | 3 | 5 | 4 |

| Taiflex 5 | 1 | 1 | 1 |

The Chairman is not included (for all factories).

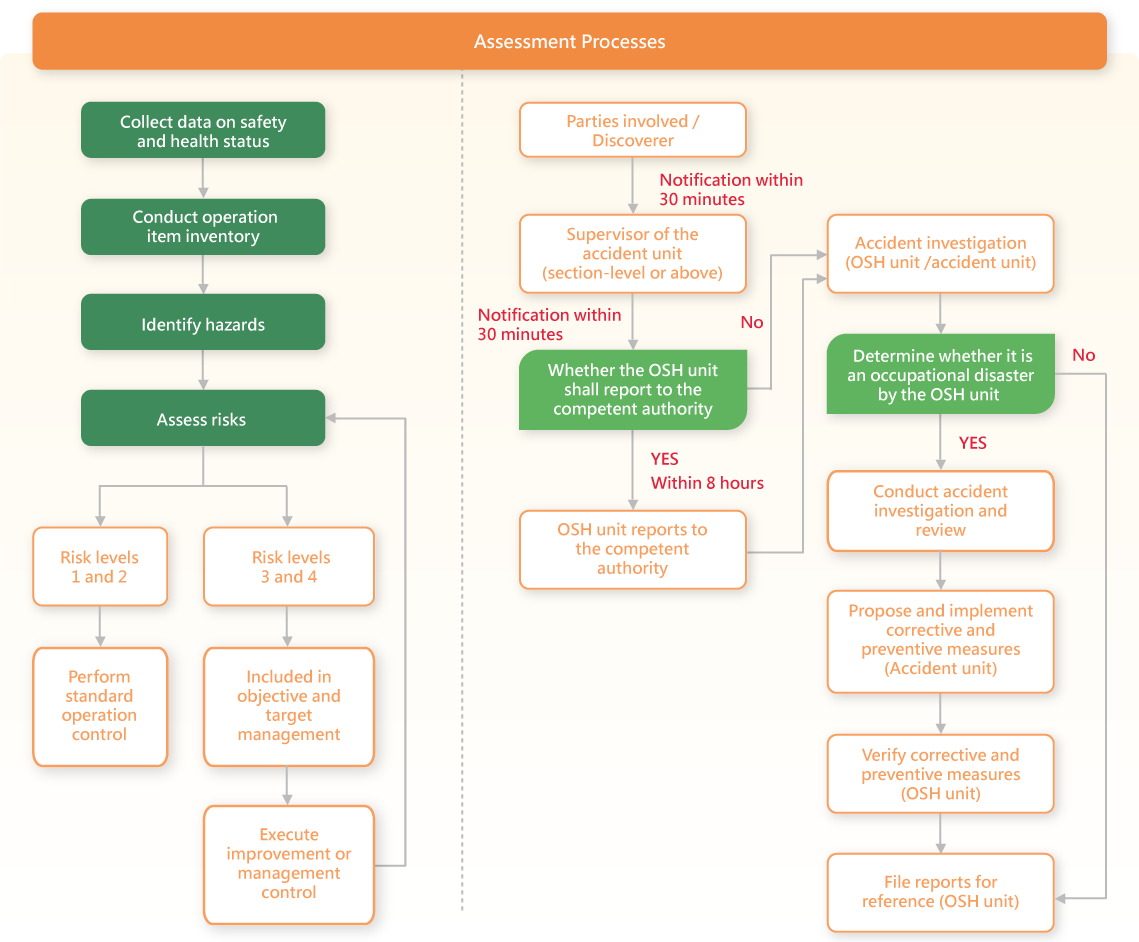

Through the hazard identification team comprising of seed personnel of each unit, we proactively evaluate factors that may cause hazards with respect to unit operations, areas, equipment, and the physical and mental status of personnel, and statistically analyze the units with higher rates of disabling injuries and the prevalent types of occupational accidents. Units with higher accident severity and recurrence are prioritized as the focus of safety communications and management.

For hazards with medium-level risk or above (Level 3 or 4), the OSH Committee would request relevant units to develop corresponding control measures with progress reviews on improvements carried out semi-annually. We also delve into minor incidents and false alarm incidents to explore feasible and efficient improvement plans and build our own safety culture.

Taiflex takes the cause of each occupational injury seriously and has established response procedures, including notification, investigation and analysis, and subsequent corrective and preventive measures, to prevent the recurrence of incidents with specific and effective improvement measures.

In 2020, Taiflex adopted ISO 45001 management system and obtained relevant certification. In 2022, we took one step further and expanded the coverage to cover all of our factories. In 2023, we obtained the Taiwan Occupational Safety and Health Management System (TOSHMS) certification. which covers all production and non-production sites, areas, equipment and routine/non-routine operations within the Company's operations, as well as activities carried out by external parties on our premises (e.g., provision of facilities and equipment to be operated within the Company, caterers, security, equipment maintenance providers, etc.)

Each factory continues to manage pursuant to the OSH system, and actively sets performance indicators with regular measurements to ensure the effectiveness and feasibility of safety and health management measures.

| Category | Total No. of Persons | Total No. of Persons Covered by the OSH System | Coverage Rate |

|---|---|---|---|

| Employee | 856 | 856 | 100% |

| Non-employee worker | 23 | 23 | 100% |

We attach great importance to occupational disaster management of all stakeholders. The monitoring scope covers employees in the Kaohsiung factories and warehouses (97%), as well as on-site external parties, contractors and other workers (3%). We also perform cause analysis on every occupational disaster, both internal and external, as the basis for risk control, incident prevention and continuous improvement of the OSH system.

All of our occupational injury data had met the internal objectives in 2023 with hard work from all employees, and there were no employee or non-employee fatalities or serious injuries due to occupational disasters. We will continue to reduce potential hazards and environmental risks through education and training, workplace inspections, hazard identification and risk assessment, internal/external audits and other mechanisms to achieve the ultimate goal of zero occupational accidents with FSI below 0.1. Please refer to Appendix I ESG Information - Social Data of this report for detailed information.

| Occupational Injury Rate/Index | 2021 | 2022 | 2023 | Target (2023) |

|---|---|---|---|---|

| No. of reported incident | 1 | 0 | 0 | 0 |

| FR | 0.63 | 1.82 | 0.63 | <1.5 |

| SR | 4.4 | 3.64 | 1.26 | <3.6 |

| FSI | 0.05 | 0.08 | 0.03 | <0.1 |

| Fatal occupational injury rate | 0 | 0 | 0 | 0 |

| Category | Item | 2021 | 2022 | 2023 | |

|---|---|---|---|---|---|

| Employee | Working hours | Total working hours of female employees | 364,104 | 386,344 | 388,664 |

| Total working hours ofmale employees | 1,232,200 | 1,263,096 | 1,201,112 | ||

| Total working hours | 1,596,304 | 1,649,440 | 1,589,776 | ||

| No. of recordable occupational injuries (including the number of fatalities and serious occupational injuries) | Total number of female occupational injuries (times) | 2 | 1 | 0 | |

| Total number of male occupational injuries (times) | 1 | 2 | 1 | ||

| Total number of occupational injuries (times) | 3 | 3 | 1 | ||

| Fatality rate of occupational injuries | 0 | 0 | 0 | ||

| Rate of severe occupational injury | 0 | 0 | 0 | ||

| Rate of recordable occupational injury | 1.88 | 1.82 | 0.63 | ||

| Non-employee | Working hours | Total working hours of female employees | 2,710 | 11,520 | 0 |

| Total working hours of male employees | 13,713 | 42,240 | 32,206 | ||

| Total working hours | 16,423 | 53,760 | 32,206 | ||

| No. of recordable occupational injuries (including the number of fatalities and serious occupational injuries) | Total number of female occupational injuries (times) | 0 | 0 | 0 | |

| Total number of male occupational injuries (times) | 0 | 0 | 0 | ||

| Total number of occupational injuries (times) | 0 | 0 | 0 | ||

| Fatality rate of occupational injuries | 0 | 0 | 0 | ||

| Rate of severe occupational injury | 0 | 0 | 0 | ||

| Rate of recordable occupational injury | 0 | 0 | 0 | ||

In order to eliminate potential operation hazards, the OSH Management Division carries out internal voluntary inspections on a monthly basis. Audits are conducted on five major areas within the daily operation, i.e., chemicals, machinery and equipment, on-site environment, fire safety equipment and waste treatment, to ensure the effectiveness of the existing management controls and monitor the improvement progress until it is completed.

To instill the culture of workplace safety and health, and to promote safety and health protection and operational safety awareness among employees, the Company regularly organizes on-thejob training for existing employees. New recruits are to attend the general OSH education and training when they report to work. Assessments would be conducted to establish fundamental occupational safety concepts. Please refer to Appendix I ESG Information - Social Data of this report for detailed annual training information.

| Training Item | No. of Trainees | Training Fee (NT$) |

|---|---|---|

| General on-the-job OSH education and training in 2023 | 624 | 0 |

| Training for prevention of rights violation at workplace in 2023 | 442 | 0 |

| Traffic safety promotion in 2023 - Recognize signs and markings in the industrial park - safe driving | 590 | 0 |

| Fire safety training for new recruits | 42 | 0 |

| General hazard education and training | 387 | 0 |

| First aid training course (CPR+AED) | 14 | 0 |

| On-the-job training for supervisors of specific chemical substance operations | 3 | 2,400 |

| Training for operators of specific high-pressure gas equipment | 2 | 9,600 |

| Training for personnel transporting dangerous goods | 1 | 3,200 |

| On-the-job training for personnel transporting dangerous goods | 1 | 3,000 |

| Training for forklift operators | 5 | 19,000 |

| On-the-job training for forklift operators | 10 | 5,000 |

| On-the-job training for boiler operators | 1 | 2,400 |

| On-the-job training for supervisors of hypoxia operations | 1 | 500 |

| On-the-job training for operators of fixed cranes | 3 | 1,500 |

| On-the-job training for supervisors of organic solvent operations | 2 | 1,600 |

| On-the-job training for first aid personnel | 2 | 1,000 |

| Training for operators of fixed cranes under 3 MT | 1 | 3,500 |

| Preliminary training for security inspectors | 1 | 2,700 |

| Annual 3-hour radiation protection training | 1 | 800 |

| Total | 2133 | 56,200 |

Trainees include both employees and on-site external parties.

In view of the fact that many occupational hazards do not happen to employees but to nonemployees, Taiflex strives to enhance the safety of our work environment. We collaborate with on-site lessors through mutual support with regular safety meetings held by both parties to strengthen the safety of the common operating environment. Personnel of contractors entering the premises must undergo safety and health education and training beforehand and be informed of operational hazards to ensure the overall safety within the factory.

Taiflex also conducts regular audits on all partners in accordance with the supplier management procedures, with strengthened supervision and management measures for contractors performing high-risk operations on site in particular. Deficiencies identified during audits shall be improved by the prescribed deadlines, otherwise there will be fines or penalties including work suspension. In 2023, we audited and provided assistance to four suppliers, with 14 negative observations identified.

The Company regularly conducts various emergency drills to assess the feasibility and applicability of the overall emergency response measures in the event of a disaster. Starting from 2021, we have included stakeholders such as contractors and lessors in our emergency drills to enhance the multi-hazard disaster response and prevention concept of both internal and external parties, thereby improving the effectiveness of our disaster notification and communication system. In 2023, we have continued with these practices to ensure comprehensive training for all types of workers in all factories, aiming to minimize the damage of potential disasters and accidents.

At Taiflex, our goal extends beyond achieving zero workplace accidents. We recognize that employee health is fundamental to the stable operation of our business. Therefore, we provide comprehensive workplace health management services to our employees. Through various management measures, professional consultations, courses, and activities, we are committed to promoting the physical and mental well-being of our employees.

Unsafe work environment and practices may result in occupational disease or injuries. Besides direct damage on the safety and health of employees, it has an indirect impact on the Company's productivity. In order to improve the physical and mental health of employees, Taiflex conducts regular assessments on five major types of physical and mental injuries and implements improvement and enhancement measures to prevent the occurrence of occupational hazards and injuries.

The Company engages accredited hospitals to provide employees who have been employed for more than one year with free annual health check-ups that are superior to regulatory requirements, as well as special health examinations for those involved in tasks with special health hazards to verify whether there is any health impact from their work environment or tasks. We take the initiative to arrange employees with abnormal health examination results, maternal employees, employees with excessive workloads as well as ones impacted by occupational disasters to consult with medical specialists. For employees classified as above the stratification, the on-site doctors would evaluate the health status and job functions of these employees to advise on the appropriateness of job arrangements.

For an effective implementation of health check-ups and as the foundation for workplace health promotion and occupational disease prevention, we provide health check-up leave with pay. Additionally, employees’ family members can undergo health check-ups at a group discount rate. We encourage employees to care about their health conditions. In 2023, the compliance rate with health checkup regulations was 100% with zero cases of occupational disease.

| Item/Year | 2021 | 2022 | 2023 |

|---|---|---|---|

| General health check-ups | 680 | 692 | 755 |

| Special health check-ups | 120 | 107 | 99 |

Through the use of the internal employee portal, Taiflex electronically manages employee health and continuously improves healthcare efficiency. At the same time, we have established a Safety and Care Zone as well as an Employee Assistance Section to help colleagues detect physical and mental health issues, receive timely treatment, and adopt healthy lifestyles, thereby improving individuals’ health conditions. We also use the UOF mobile app to promptly notify employees of any health abnormalities along with comprehensive health education information, as well as offer updates on the latest health knowledge and resources available.

| Activities | Description | |

|---|---|---|

| 1 | Provision of health information |

|

| 2 | Health seminar |

|

| 3 | Weight management & weight loss program (Based on statistics for 2023) |

|

| 4 | Blood donation events |

|

| 5 | Free influenza vaccine administration |

|

| 6 | Charity road race |

|

| 7 | Basketball game - sports competition |

|