In the process of natural resource extraction, there are risks of energy consumption, water pollution, land loss or human rights violations. Besides securing the quality, delivery and prices of raw materials, Taiflex must ensure that suppliers implement environmental protection, energy saving and carbon reduction, safety and health improvement, and human rights protection to meet the customer and regulatory requirements and jointly fulfill corporate social responsibility

Taiflex strongly believes that the sustainable growth of supply chain has certain influence on corporate long-term developments. Therefore, we urge suppliers to fulfill their corporate social responsibilities; carry out environmental protection, energy conservation and carbon reduction measures; improve safety and health; respect human rights; as well as maintain sound risk management and sustainable operation plans, thereby building a stable and sustainable supply chain together.

Over 90% of the Company's procurement items are goods used in production (raw materials) and packaging (supplies). Raw materials include copper, PI (polyimide), TPI (thermoplastic polyimide) and PET film, most of which need to be imported from abroad. Efforts are being made to increase the use of recycled copper. In terms of supplies, we actively utilize recycled paper and promote the reuse of wooden pallets.

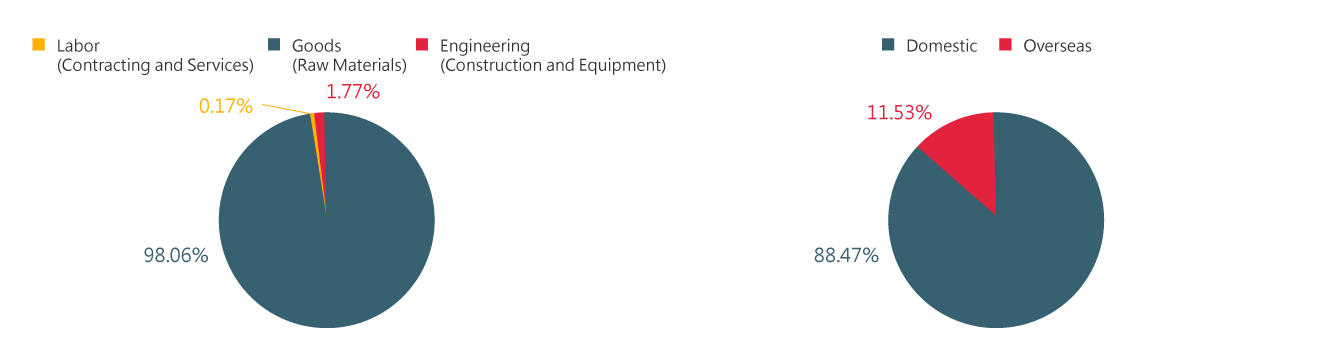

In recent years, the Company has continued to increase the number of suppliers for key raw materials and process equipment. By 2023, the percentage of local purchases has exceeded 88.47%. Please refer to Appendix I ESG Information - Economic Data of this report for detailed information on the procurement categories and percentages.

Developments of the electronics industry have always been highly dependent on the use of minerals. The global consensus has now leaned towards the use of conflict-free minerals to protect human rights. To fulfill our corporate social responsibilities, we comply with the “conflict minerals disclosure requirements” under Rule 13p-1 of the U.S. Securities Exchange Act of 1934 promulgated by the US Securities and Exchange Commission (SEC) for our conflict minerals management. We implement self-audits on social responsibilities and avoid sourcing minerals from conflict-affected and high-risk areas.

All suppliers of raw materials which use or contain minerals shall comply with the Company's policy and use the Conflict Minerals Reporting Template (CMRT) as an investigation tool in providing investigation results. The requirement of not sourcing conflict minerals from conflict regions is imposed since new supplier selection. As for existing suppliers, besides signing the agreements or statements which ban the use of conflict minerals, we carry out due diligence through annual supplier audits and lot traceability.

Copper is the most widely used metal in our production of FPC materials. Besides mining new minerals, recycling from existing applications or electronic products has become the trend. About 90% of copper foil factories worldwide use recycled copper as raw materials. Thus, Taiflex cooperates with key suppliers of copper foil and maintains the use of recycled copper foil at a certain degree, contributing to the reuse of resources and the sustainable development of the planet. Furthermore, the cost advantages, the precision required in ED copper foil process as well as the greater flexibility in width and thickness adjustments allow recycled copper to be widely used in various electronic products. We purchased 158 MT of recycled copper in 2023.

GP documents shall be provided or updated for the introduction of new materials and the regular purchases of materials. We integrate green supply chain to service our customers and initiate the reduction and reuse of packaging materials within the supply chain. Since 2020, our principles of green procurement management have been delivered to suppliers along with our orders through the e-procurement system while we promote the green procurement concept to suppliers. We adopt standards above the regulatory requirements to prevent or mitigate adverse environmental impact, thereby enhancing the Company's operational resilience under climate change crisis.

Taiflex has established a supply chain management framework to manage relevant risks and prompt suppliers to advance together to create greater shared value and influence. In 2017, the RBA was adopted as the assessment standard for supplier management. It covers areas including labor, health and safety, environmental protection and business ethics. Since 2020, we have been referring to the Supplier Relationship Management (SRM) platform for suppliers to perform order maintenance, delivery confirmation, shipment query, acceptance query, return order query, etc. in a more efficient manner, thereby reducing information gap and increasing communication accuracy.

In addition, Taiflex has established risk control mechanisms for supply chain disruptions. In the event of supply chain disruptions caused by external factors (e.g., natural disasters, diseases, major global events, etc.), emergency response procedures would immediately be initiated. Relevant departments including procurement, quality assurance and production planning would quickly review aspects such as raw materials stocktaking, supply of materials from alternate suppliers, elevation of raw materials inventory level and material consumption during process, and swiftly draw up a contingency plan.

Taiflex regularly conducts “Supplier Green System Evaluation” on key suppliers through two main approaches: “on-site audits” and “document reviews.” This is done to strengthen suppliers’ sustainability management mechanisms and ensure their implementation of sustainability initiatives. Green evaluation covers three aspects: Quality system (economic), HSPM system (environmental) and ESG (social). Suppliers shall provide feedback on their implementation of sustainability actions along with relevant management system certifications. This not only allows the Company to understand their sustainability efforts but also help them to enhance their management of sustainability risks. In 2023, a total of 44 supplier audits were conducted (13 onsite audits and 31 document reviews of suppliers). All deficiencies identified were addressed and closed, achieving a completion rate of 100%, and none of the suppliers were disqualified as a result of the audit.

In addition, the Company conducts annual assessments of suppliers in five aspects: quality, procurement, research and development, technology and shipment fulfillment rate. Transactions would be suspended for raw material suppliers who fail the assessment. They would be given a deadline for improvement and subjected to a follow-up audit after six months. Suppliers would be disqualified if improvements were not made. For supplies suppliers who fail the assessment, transactions would be suspended for at least one year, except for sole suppliers. In 2023, a total of 91 suppliers were assessed (44 raw materials suppliers and 47 supplies suppliers). One supplier failed the assessment with follow-up actions completed, achieving a 100% improvement rate.

Taiflex requires all raw material suppliers (including new/existing ones) to comply with the quality management system, the environment, safety and health (ESH) management system and the AEO assessment. Through our procurement procedures, we examine suppliers by indicators including basic corporate information, relevant certifications, quality assurance records, ESH management investigation, operation, product information, manufacturing process, raw material suppliers, financial status under business continuity management, procurement contracts, green product management, and social responsibilities.

Supplier quality assessment items include return rate of incoming materials, number of major abnormalities, number of open cases, and green suppliers (the item is assessed based on responses in the GPM system). The assessment conducted by the quality assurance unit is part of the supplier audit with a weighting of 40%. The average assessment result in 2023 was outstanding.

In the selection process for raw material suppliers to become part of Taiflex's supply chain, besides third-party verification of ISO9001 and ISO14001 compliance, suppliers shall commit to complying with the corporate social responsibility standards set out in the “Taiflex Supplier/ Contractor Corporate Social Responsibility Commitment” (CSR Commitment) before signing the contracts. The CSR Commitment is established for suppliers to understand and adhere to corporate sustainability. It encompasses the Code of Conduct for suppliers and contractors, RBA Code of Conduct, and rules and requirements pertaining to conflict-free minerals. We currently have 63 raw material suppliers, and all of them have signed the CSR Commitment (or provide relevant declaration documents). We will work on having all suppliers to follow suit.

We place great importance on the sustainable management of the entire supply chain and enhance its management performance with systemic measures including supplier assessment, audit, counseling and improvement programs for audit deficiencies, performance evaluation and supplier recognition conference on the basis of cooperation and mutual assistance. We also raise suppliers’ awareness of corporate social responsibility and business ethics principles through promotion and take appropriate measures to ensure our suppliers comply with legal requirements on environmental, health and safety, and labor issues. They shall not only meet the local statutory minimum wage requirements but also provide employees appropriate levels of wages, as well as commit to the highest ethical and moral standards in their business.

In our 2023 Supplier Conference, we expressed our gratitude towards suppliers’ support and outstanding contributions over the past year, and recognized seven excellent suppliers for their efforts. The Supply Chain Center shared our visions with and communicated our requirements in terms of quality, technology, delivery, service, cost and sustainable management of supply chain to our partners during the meeting, stressing our goal of overcoming challenges together to achieve better performance.