With increasing global attention on the issue of global warming, countries are pushing renewable energy and netzero carbon emission regulations to mitigate climate risks. Enterprises that do not transition towards green energy and net-zero emissions may risk impacting their market competitiveness and brand value.

In recent years, climate issues have become a prominent international concern. From governments to private enterprises, all sectors are striving for the goal of net zero by 2050. Global consumer electronics brands have gradually proposed to achieve 100% carbon neutral supply chain by 2030. Although we are not a direct supplier to the brand, we still actively map out our carbon reduction goals so as to jointly contribute in cooling down the planet. Since 2022, we have implemented the ISO 14064- 1:2018 GHG inventory system and obtained a third-party verification statement. In 2023, we further enhanced our carbon emission management by introducing an information-based carbon emission management platform, thereby strengthening our monitoring and management effectiveness of carbon emissions.

To effectively reduce carbon emissions, we introduce new equipment to improve our processes and proactively adjust our internal energy structure. In 2023, electricity and natural gas accounted for 69.77% and 30.00% of our primary sources of energy consumption, respectively, and the total energy consumption had a year-overyear decrease of 6.66%. However, due to a decrease in revenue, the energy intensity in 2023 dropped only slightly compared to 2022, while the carbon intensity exhibited a greater degree of decrease in comparison. Please refer to Appendix I ESG Information - Environmental Data of this report for detailed information on energy consumption and carbon emissions for the past three years.

The inventory scope aligns with the disclosure scope presented in this report (including Taiflex 1, 2, 3 and 5, and excluding the Linkou office and subsidiaries).

In response to the national energy saving goal, we continue to invest in various energy saving measures. In 2021, the ISO 50001 Energy Management System Platform was established at our Kaohsiung factory in Taiwan. Through the e-energy management platform, the Company can implement comprehensive energy inventory and set various performance indicators as well as the best power consumption strategy for equipment to ensure the optimal use of energy, thereby achieving the targets of carbon emission management.

In 2023, we implemented 29 energy-saving projects under ISO 50001. These projects were categorized into 11 types, with 9 of them focused on electricity-saving and achieved a saving of 1,504,834 kWh, exceeding the annual target of 1% stipulated in the Energy Administration Act. The remaining 2 types were extensions of projects initiated in 2022, focusing on equipment replacement and updates. These projects saved 237,649 m3 of natural gas along with a reduction in the use of synthetic adhesives containing VOCs. Of the 11 types of projects, the ones with greater energy-saving and carbon-reduction benefits achieved a reduction of 1,236.00 MT of CO2e emissions, which was roughly equivalent to the annual carbon sequestration of 3.2 Daan Parks. Please refer to Appendix I ESG Information - Environmental Data of this report for detailed information on energy-saving action plans and the associated carbon reduction benefits.

According to the Council of Agriculture, each hectare of forest can sequester 15 MT of carbon dioxide per year. Therefore, Daan Park (25.8 hectares) can absorb 384.6 MT of carbon dioxide annually.

| Measures | Expenditure (NT$10 thousands of dollars) |

Savings on Energy | Energy Saving (GJ) |

Carbon Reduction (MT CO2e) |

|

|---|---|---|---|---|---|

| Electricity | 1.Improvements on air conditioning to optimize energy efficiency | 5 | 165,808 kWh | 596.91 | 81.91 |

| 2.Replacement of water towers to conserve energy | 123.1 | 221,061 kWh | 795.82 | 109.20 | |

| 3.Installation of frequency converter on equipment to conserve energy | 185.3 | 586,596 kWh | 2,111.75 | 289.78 | |

| 4.Replacement of heat dissipation materials in NMP cooling towers at Taiflex 3 | 19.5 | 54,208 kWh | 195.15 | 26.78 | |

| 5.Optimization of FFU in clean room | 0 | 55,631 kWh | 200.27 | 27.48 | |

| 6.Improvement of lighting | 22.5 | 70,736 kWh | 254.65 | 34.94 | |

| 7.Reduction of cooling load to conserve energy | 0 | 228,673 kWh | 823.22 | 112.96 | |

| 8.Adoption of routine operation for ventilators at toilets | 0 | 2,358 kWh | 8.49 | 1.16 | |

| 9.Oven pre-heating with nitrogen to conserve energy | 29.1 | 119,764 kWh | 431.15 | 59.16 | |

| Total | 384.5 | 1,504,835 kWh | 5,417.41 | 743.37 | |

| Natural Gas | 10.Replacement of ceramic media within the RRTO at Taiflex 2 to conserve energ | 421 | 193,070 m3 | 6,466.76 | 399.99 |

| 11.Adoption of auxiliary fuel for zeolite rotor concentrator at Taiflex 3 to conserve energy | 2000 | 44,579 m3 | 1,493.15 | 92.63 | |

| Total | 2421 | 237,649 m3 | 7,959.91 | 492.62 | |

| Total for 2023 | 13,377.32 | 1235.99 | |||

On December 31, 2020, the Bureau of Energy, Ministry of Economic Affairs announced that major electricity users with contracted capacity of 5,000 kW or above are required to install renewable energy power generation equipment for 10% of their average chartered capacity in the previous year within five years, purchase renewable energy and certificates, or install energy storage facility in order to perform their obligations pursuant to the “Renewable Energy Development Act.” The contracted capacity of our factories has yet to meet the threshold of major electricity users. Although we are not subject to the aforementioned regulations at this stage, we took actions in response to the government policy. We established Taiflex Green Power in March 2021 and installed PV facilities of 375.9 kW (generating 450,752 kWh of electricity per year) at Taiflex 2 in 2022. At the same time, we bought back the installed capacity of 271.2kW (generated 349,544 kWh of electricity per year) previously leased to other companies at Taiflex 5.

To achieve net zero emissions, we have set medium to long-term goals: the global vision of “10% renewable energy, low carbon emissions, and circular economy for waste by 2030” and “100% renewable energy, net zero emissions, and 100% circular economy by 2050.” We adopt green building initiatives when enhancing energy efficiency and production at our Kaohsiung factories and as priorities for the design of our Thai factory. We also plan to sign a ten-year purchase agreement for green power certificates of 75 GWh, making carbon reduction our competitive edge. Furthermore, following assessment by the Sustainable Development Committee and approval by the Board of Directors, our subsidiary, Taiflex Green Power, will expand efforts on renewable energy installation and be dedicated to the operation of our green power facilities. In 2023, an additional investment of NT$12,827 thousand to increase installed capacity by 271.2 kW was made in Taiflex 5.

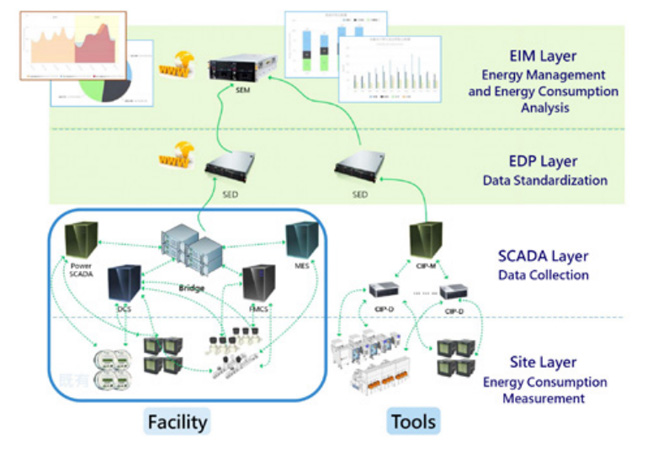

Taiflex continues to demonstrate ongoing efforts in sustainability initiatives. In 2023, we introduced an information-based carbon emission management platform to monitor and manage operational carbon emissions more effectively. This action embodies the Company's commitment to sustainable development and lays a solid foundation for our carbon reduction pathway.

The carbon emission management platform follows the ISO 14064-1 standard to organize GHG data within the organization. Transitioning from the previous offline data collection using Excel, we now have data collection units of various activities inputting data directly into the carbon emission system. Once the system automatically runs the calculations, comprehensive information such as the Company's total carbon emissions, carbon emission hotspots in factories, and categories are clearly presented. The implementation of this system significantly enhances the accuracy, transparency, and traceability of carbon inventory information.

During the implementation, Taiflex focuses on improving data resolution. By delving into data structure and recording factory carbon emissions on a monthly basis, the numbers can serve as more timely operational decision-making indicators. Linking supporting data with each record through the platform improves the clarity of supporting data and consequently the sources of emissions for traceability, making the system trustworthy and wellreceived by verification personnel. Source analysis of emissions and efficiency improvement of data collection provide decision-makers with more concrete data and significantly reduce the workload of the execution units.

We plan to extend the management system to each subgroup for implementation of a group-wide GHG inventory in order to effectively manage the carbon emissions of Group subsidiaries, and comply with the requirements for GHG inventory of groups and their subsidiaries outlined in the Sustainable Development Action Plans for TWSE- and TPEx-Listed Companies by the Financial Supervisory Commission. Furthermore, we would leverage more real-time data to assist the management in understanding carbon emissions within the organization and strengthen our carbon management efforts with carbon reduction projects of various departments, striving to achieve the Group’s net zero goal by 2050 and become a global expert of environmentally friendly materials.