“To become a world-class FPC material provider” has always been our vision. We persistently advance on our three core technologies of formula R&D, precision coating and testing methods, in order to develop materials that meet market demands and to become a global leader in FPC materials.

Taiflex was co-founded by professionals from the Industrial Technology Research Institute (ITRI) and the electronic materials field in Taiwan. With industry-leading technology, we are the largest FPC material supplier in the Greater China Region. Taiflex not only invests enormous resources in in-house R&D but also works closely with upstream international material manufacturers and equipment design companies with advance technology. Also, we carry out R&D projects on the transfer of coating technology and formula analysis through collaboration with ITRI and National Sun Yat-sen University. By combining R&D resources through industry-government-academiainstitute collaborations, we work with end customers in developing the next-generation products, committing to the provision of advanced FPC materials and integration of innovative applications. Please refer to Appendix I ESG Information - Economic Data of this report for detailed information on Taiflex's participation in external industry associations.

In addition to our long-term involvement with FPC materials, we have expanded our business to include advanced packaging materials for semiconductors and display as well as high-precision coating manufacturing services by leveraging our three core technologies of formula development, precision coating, and testing methods accumulated over the years. We established the 100%-owned subsidiary, Taichem Materials Co., Ltd., through spinoff in September 2020 to provide customers with more diversified and customized solutions.

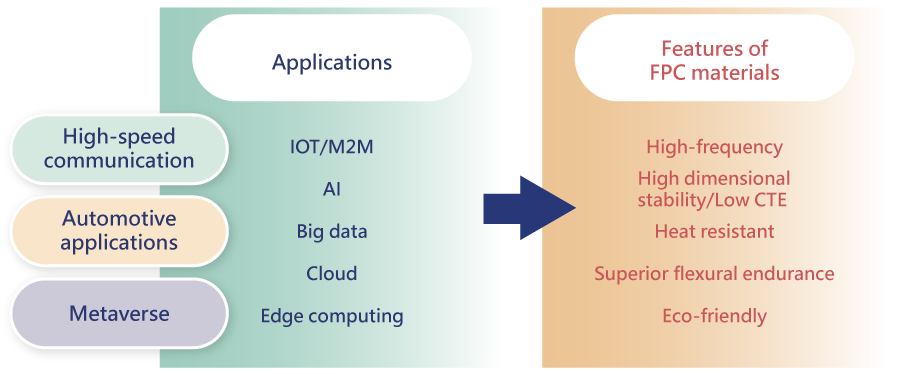

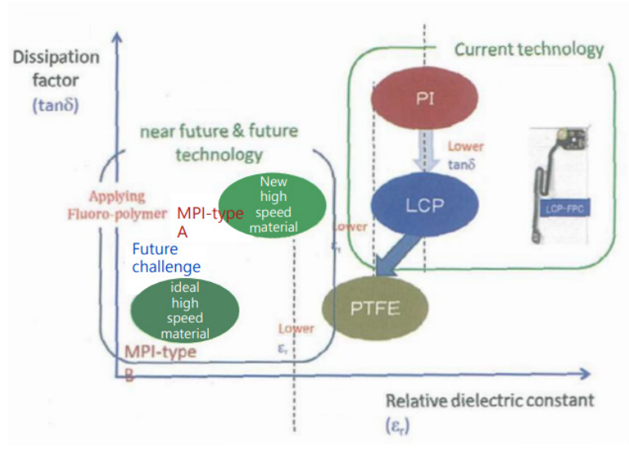

The rising proportion of 5G communication over the years along with the demand for high data transmission and robust developments in the new energy vehicle segment drive major material companies and brands to shift towards high bandwidth and low latency applications. Since highspeed signal transmission suffers greater insertion loss, applications mostly opt for materials with low Dk/Df. Besides LCP and MPI which are common in the market, our R&D Center is aggressively developing fluoro-based materials with lower Dk and Df values.

Nevertheless, the focus shall not be placed merely on understanding the material but also its subsequent processability and economic value in the market during product development. Fluorobased materials have high electronegativity, and thus external polarization has minimal influence on molecules. It is therefore an excellent material for high-frequency applications. However, the material itself is difficult to process in the subsequent stages.

Taiflex excels in materials and coating technology. Combine these with our top-notch laminating technologies; testing equipment with the most rigorous and highest specifications and control standards for product appearance and FCCL properties; and extensive research resources, equipment and human capital in FCCL, we provide the new information generation with the best high-frequency materials.

As electronic products continue to develop in the direction of being thin, light, multi-functional and high-performance, the demand for FPC rises and creates abundant business opportunities. Taiflex will continue to focus on technology and invest more than 3% of our annual sales in R&D. Through continuous research and innovation, we aim to provide the market with superior and more diverse choices of materials and a wide range of applications. We expect our new products to enjoy significant growth in automotive, meta-universe and wearable segments in the future.

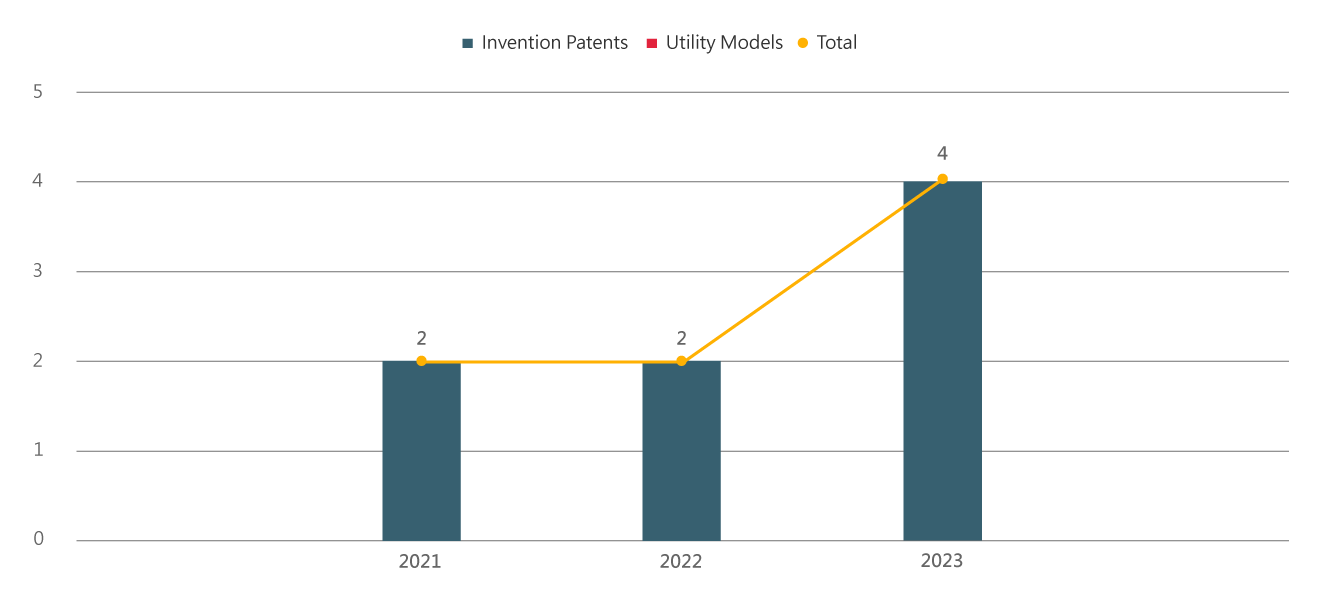

Taiflex places utmost importance on R&D innovations and recognizes IP as one of the core assets of the organization. During technology development, the Legal and Intellectual Property Center would assist the R&D Center in patent search and literature analysis to stay current on existing patents, thereby avoiding infringement of others’ rights and securing our freedom to operate. Once the development stage is over, R&D results shall be properly maintained and managed to avoid data breach, or protected via patent applications to create a competitive niche for our operation.

Also, the Legal and Intellectual Property Center regularly maintains and evaluates our patents and R&D results under protection, analyzes IP value based on the intelligence collected, and commercializes our IPs through patent licensing or technology transfer to increase the economic benefits and lower the operating costs of IP.

In order to enhance the value of Taiflex among international brands, build goodwill, and sustain the competitive advantage of our product technology in the market, we continue to maintain effective patents worldwide. As of 2023, we had 247 global patent applications and up to 84% of them were invention patents in the major markets of Taiwan, the U.S., Japan, Europe and mainland China, with 150 applications approved. We aim to continuously expand our IP portfolio regarding our core technologies and R&D achievements.

In the face of global business competitions and complex supply chain relationships, trade secrets protection has become one of the competitive edges for securing a company's future core competitiveness. Trade secrets include technologies, methods, processes, formulas, programs, designs or other information that can be used for production, sales or operation, and meets the requirements of confidentiality, economic value, and the adoption of reasonable confidentiality measures. With respect to trade secrets concerning key formula and process, we registered four cases for management in 2023 (there were no concerns over leakage of customer privacy), with a cumulative total of 15 cases. We introduced ELN in 2021 to reinforce our control over R&D achievements, thereby furthering our technological advantages.

For employees to have correct understanding on IP management system, Taiflex has adopted the Taiwan Intellectual Property Management System (TIPS) since 2014 to establish a systematic management system which conforms to the nature of our technology research and development and links IP management with operational objectives. In recent years, we have continued to improve IP acquisition, protection, maintenance and utilization, and obtained the Level-A TIPS certification in 2023. With further improvement on IP management, we reduce the risk of intangible assets management, thereby enhancing our overall profitability and operation performance.

We understand trade secrets have high commercial value and importance to corporate operations. Besides protecting our research achievements through patent applications, we have adopted ISO27001 Information Security Management System in 2016, established the Intangible Assets Security Committee and formulated the Confidential Information Protection Policy to manage the Company's confidential information. By establishing a sound trade secret protection management mechanism, actions including the inventory, classification and labeling of confidential information, identification of ownership over IP rights, signing of confidentiality agreement, control over information security, retention of records, early warning, audits, annual assessment on the protection of confidential information as well as training and promotion of information security are taken to minimize the risk of trade secret leakage.

On October 13, 2023, Taiflex's Knowledge Management (KM) was officially launched under the leadership of the President. With tea being the theme, the kickoff meeting used tea as a metaphor for knowledge, where the process of brewing tea is similar to the unfolding, extraction, and diffusion of knowledge, embodying the spirit of KM.

During the kickoff meeting, the President shared with colleagues the concept of knowledge is power, power creates value, and value leads the Company towards sustainability. By systematically categorizing, integrating, accumulating, analyzing, and applying knowledge, the power of knowledge would lead Taiflex to explore and innovate in unknown territories.

Taiflex's KM aims to “build a knowledge temple for electronic materials and become the cornerstone of sustainable operation.” It seeks to revitalize the Company's knowledge culture by establishing a learning organization, nurture precision coating through delving into innovative developments, study high-end formulas in light of global trends, complete digital transformation with smart manufacturing developments, and accelerate production scale to deploy diversification strategies, thereby leading Taiflex towards sustainable operation.

In 2023, the KM team organized a total of 25 educational, counseling and promotional activities with an average attendance rate of 74%. To drive a sharing culture and enhance knowledge exchange, the team carried out promotional activities in five ways: printed materials, electronic media, events, promotional materials, and systems. In 2024, it will continue to promote the transfer and utilization of knowledge and experience as well as accelerate R&D innovations on a solid foundation to enhance competitiveness and create sustainable value.