Having product quality meets customer requirements is mandatory for Taiflex to “become a world-class FPC materials provider.” We shall provide appropriate resources to maintain the integrity of our quality assurance system and ensure our products meet regulatory requirements in order to strike an optimal balance between the Company and our customers.

Taiflex is dedicated to the process research, manufacturing and selling of FCCL. Upstream suppliers of the industry are PI/copper foil materials providers while downstream customers are FPC manufacturers. We maintain continuous communication with customers throughout the production and sales stages, providing weekly feedback on future global demand to the Headquarters and later translating the feedback into production plans. We collaborate with companies in the supply chain to form a comprehensive industry value chain and pursue maximum benefits for the Company while meeting customer demands.

Raw materials

Chemicals

Equipment vendors

FCCL

CVL cover-layer

Stiffener

Chemical composite

FPC & PCB

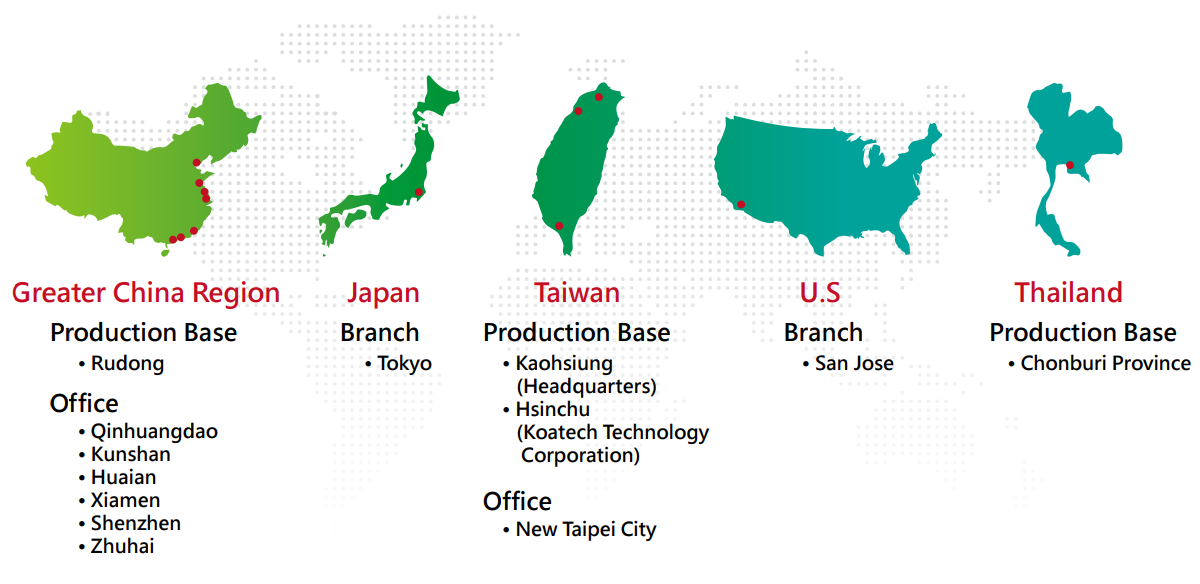

Insulating tape

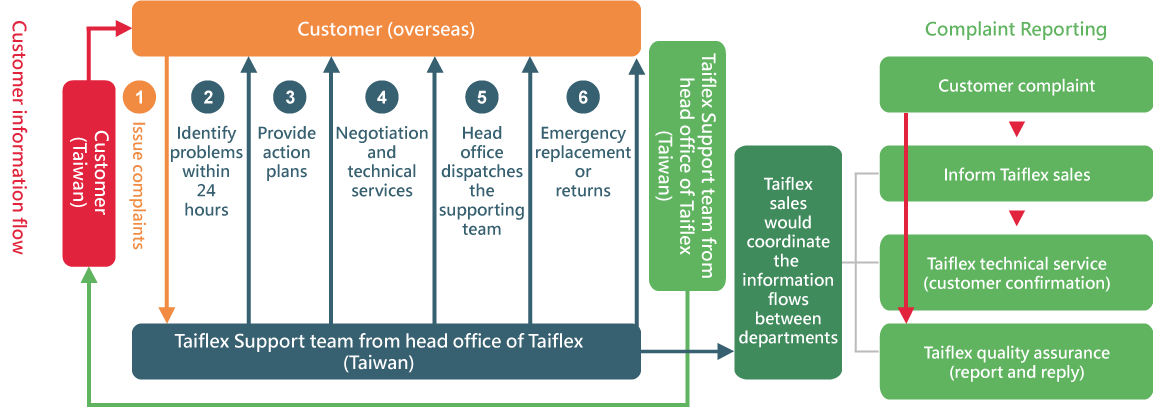

Customer satisfaction is at the heart of our management philosophy. We are committed to deliver innovative products and services and uphold the core values of responsibility and enthusiasm. Taiflex has dedicated units providing product services to customers and working closely with the quality assurance department to solve product issues ranging from appearance to functionality. Besides Taiwan, we have service personnel stationed at Kunshan, Shenzhen, Zhuhai, Xiamen, and Nantong to cope with production globalization among downstream customers by enhancing the accessibility and timeliness of our services. We also have offices in the U.S. and Japan, serving as a base for providing timely product services and sales.

At the product design, testing and verification stages, our Headquarters supports the technical needs of customers in Taiwan, mainland China, Europe, the U.S., Japan and South Korea to enhance service efficiency and forge a closer tie with customers. We engage in technical exchanges with customers when needed and provide technical assistance to address any issues they encounter during design and testing.

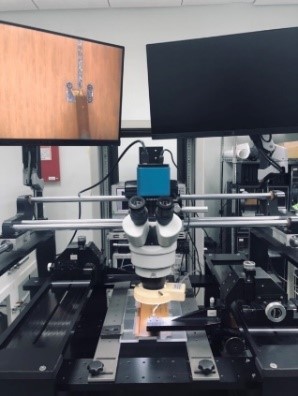

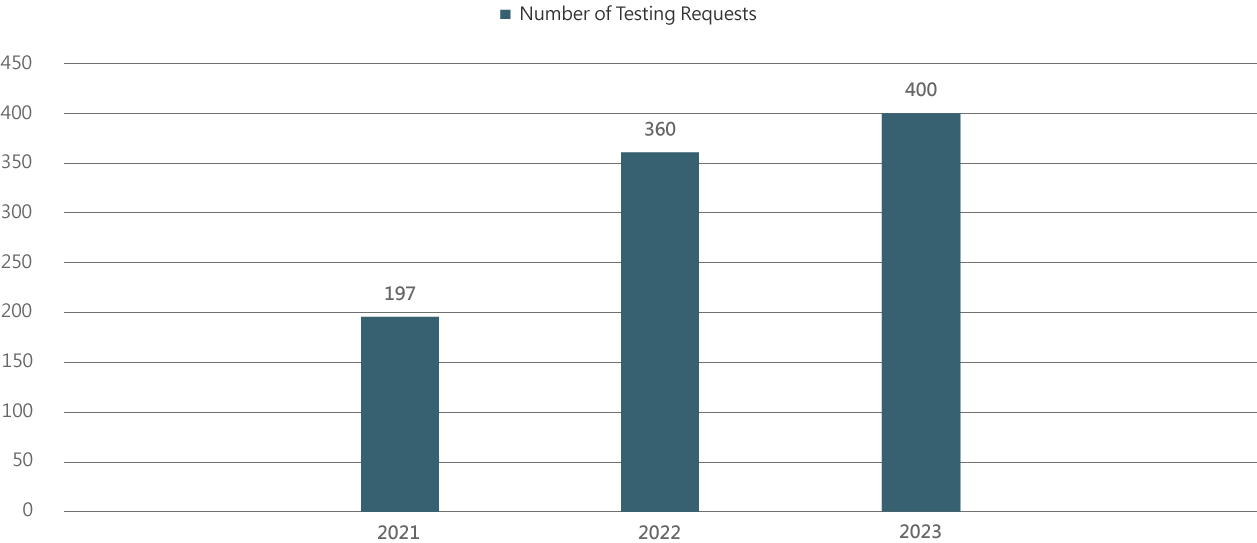

Taiflex has acquired a complete set of testing equipment including SEM/EDS, FTIR, metallurgical microscopes, TMA/DSC/DMA thermal analyzers and tension machines for internal departments as well as testing requests from customers to satisfy their needs for material analysis and characteristic testing. Besides expediting the product validation process for our customers, our technical staff can gain a better understanding of product characteristics, thereby enhancing cooperation and mutual understanding with customers.

We have restated the number of testing requests from customers for 2021 and 2022 as the numbers in the previous report were incorrect.

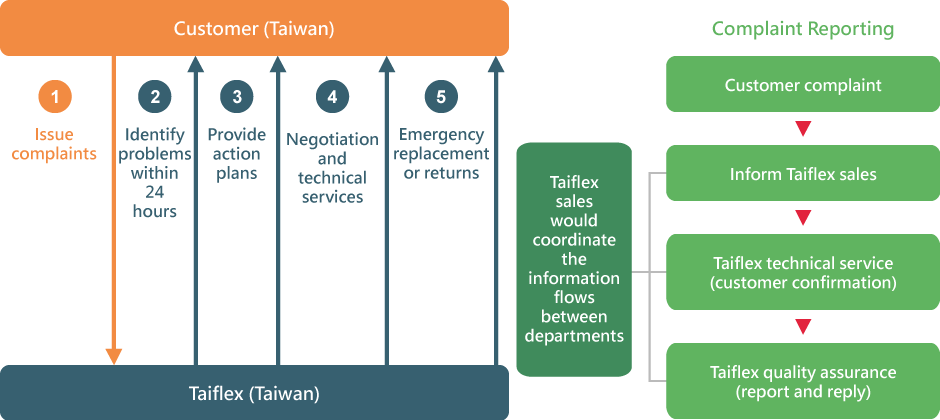

Once we identify opinions, questions or grievances raised by our customers as major customer complaints, a cross-department task force would be assembled to handle the issue. Immediate actions and timely improvement measures would be taken by production, technology, R&D and quality assurance units based on their functions and authorities to assist customers with resolving the issue as well as minimize the loss in labor, materials or equipment utilization. Our product service quality can therefore be enhanced to uphold our reputation and secure customer satisfaction.

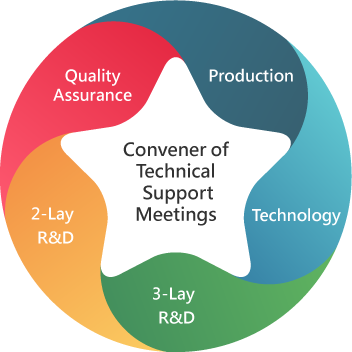

In the event of a major customer complaint, the customer service officer would hold a technical support meeting involving officers of the Production, Quality Assurance, Technology and 2-Lay and 3-Lay R&D as well as responsible engineers to discuss major defects in the product. Replies concerning causes identified in the preliminary review and improvement measures shall be given within three days, and the complete test data, cause analysis, improvement and preventive measures as well as reasonable solutions acceptable to the customers shall be provided within seven days to ease customers’ concerns.

The objective of our quality/HSF is to achieve customer satisfaction in principle. In accordance with IATF 16949 and HSPM System requirements, appropriate items and quantitative targets are determined in the management review meetings and their compliance and applicability are reviewed regularly.

As for issues raised by customers, we continue to make improvements through crossdepartmental technical meetings, quality proposals, 5S, defect rate meetings, etc., aiming to satisfy our customers’ needs as quickly as possible.

A total of 183 quality proposals were submitted in 2023. 5S activities are assigned by engineers or supervisors on a rotating basis to assess the on-site environment / safety / work practices in order to meet quality and safety requirements.

5S refers to sort, set in order, shine, standardize and sustain.

To secure product quality, we execute inspection and testing strictly at stages of incoming materials, manufacturing, work in progress, finished goods as well as shipment in accordance with the quality control plans and relevant regulations. All inspections and tests are documented to verify the products conform to relevant requirements.

In 2023, there were no incidents where quality of our products affected the safety or health of downstream suppliers and end-users nor non-compliances of laws and regulations concerning product and service labeling and marketing.

| Product or Service | Safety Regulation Certification | Percentage of Evaluated Products or Services to Customers |

|---|---|---|

| 2L FCCL |

|

100% |

| 3L FCCL |

|

100% |

| CVL |

|

100% |

| Stiffener & composite film |

|

100% |

| Bonding sheet |

|

100% |

Percentage = (Total number of evaluated products or services to customers /Total number of products or services to customers) × 100.

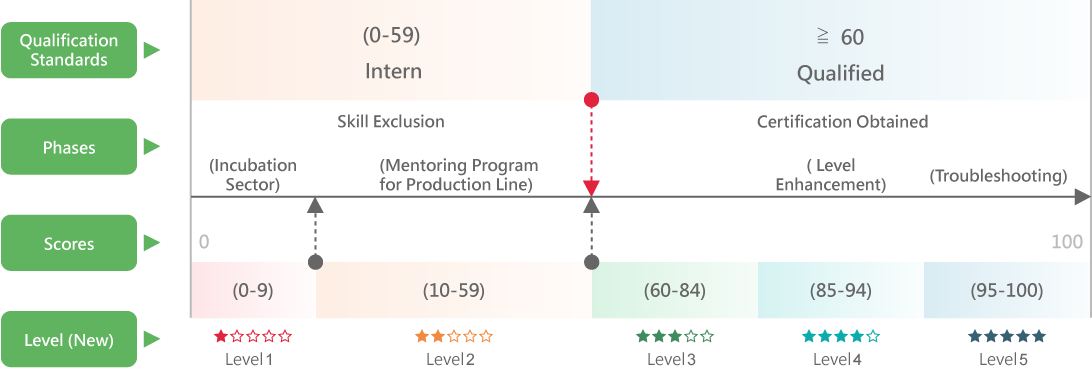

The skill proficiency of direct personnel in the Manufacturing Center is an important factor that directly affects the stability of production quality. Therefore, we have implemented a certification system (Level 1 to 5). Employees shall undergo safety and orientation training when coming aboard and only qualified employees (above Level 3) can join the production line to operate machines independently. They would receive on-the-job skill training from trainers and on-site personnel through the mentoring program.

Assessments on the on-the-job skill training include instruments and equipment operation, product appearance judgment, and troubleshooting. Assessments are conducted quarterly and annually for level advancement evaluation. Of the 340 direct personnel in 2023, 3% were at Level 2, 32% were at Level 3, 6% were at Level 4 while 59% were at Level 5. When new recruits come on board, they would be paired through the mentoring program and with training mechanism set up by the incubation sector, they shall be able to meet job requirements with adequate quality and safety awareness on schedule.

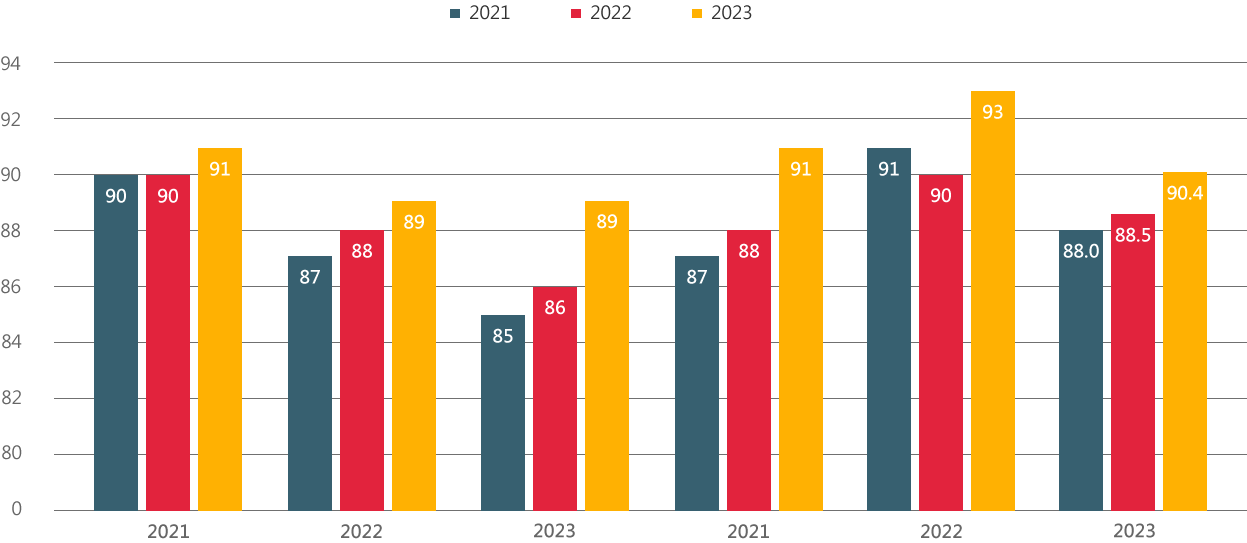

To truly understand and listen to our customers, Taiflex conducts customer satisfaction surveys every six months. Survey forms are regularly sent to target customers by sales personnel via fax or E-mail, and where necessary, contacts may be made via phone or letters. The purpose of the survey is fully explained to the customers, and they are requested to respond within the specified deadline. Once data are collected, the “Customer Satisfaction Survey Report” (including the results of customer satisfaction surveys and evaluations) would be prepared, which is then reviewed by the (assistant) managers and submitted to the (Vice) President for approval.

In 2023, we scored an average of 90.4 points in customer satisfaction, achieving the annual goal of 88 points or above. Negative feedback or failed performance from the survey would be discussed in the management review meetings for cross-department units to propose improvement schemes and recommendations as we strive to become a trustworthy longterm partner to customers.