VOC emissions from our use of volatile organic solvents in production generate secondary pollutants such as NOx and TSP even after being treated by pollution control facilities. Failure to implement air pollution emission management could negatively impact the Company's image, resulting in an allocation of more resources and hindering our GHG reduction efforts.

Without proper waste management for hazardous industrial waste from our use of chemicals, such as organic solvents, in production, apart from possible penalties, it would hinder our GHG reduction efforts.

Taiflex is committed to zero waste. Besides promoting the concept of resource conservation to employees during daily operation, we focus on process enhancement for source reduction. As we reduce the consumption of resources and materials, we also minimize the pollutants generated. For air pollution, wastewater, and solid waste which we cannot eliminate completely at present, we establish pollution control facilities or engage qualified professional companies to handle the matters. We strive to reduce the environmental impact of our operations and seek the best solution in order to gradually achieve the ultimate goal of zero pollution.

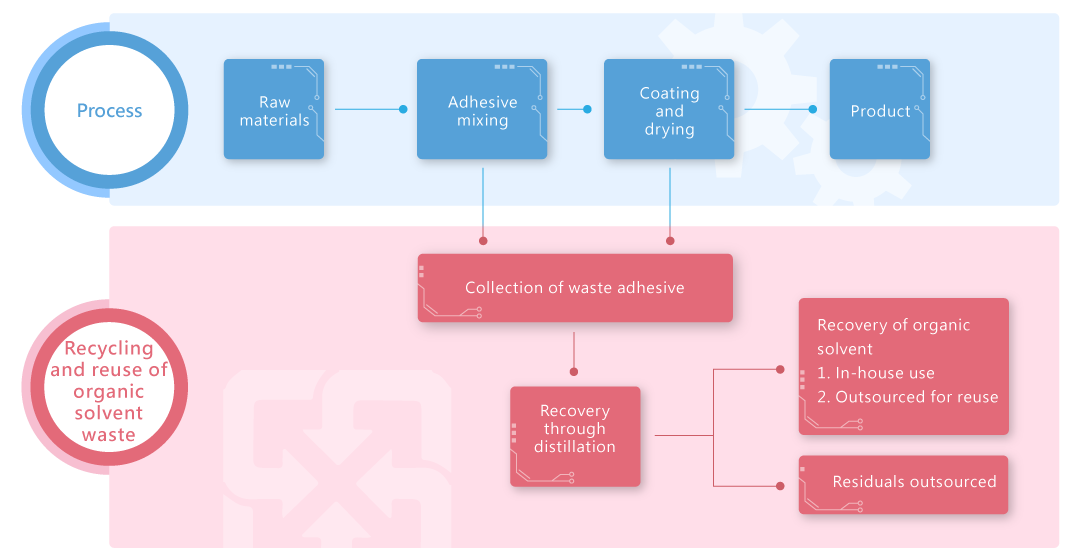

Taiflex has built a waste adhesive recycling system, which refines chemicals into industrial grade raw materials through distillation, purification and other related processes for them to be used at the production line. The recycling not only cuts down stationary pollution sources and exhaust emissions to stay environmentally friendly, but also reduces the volume of raw materials purchased to enhance the Company's competitiveness. Currently, the total recycling volumes of NMP and MEK have been increasing annually, with over 60% reused in production lines.

In 2023, we recycled 353 MT of NMP, a 15.33% increase compared to the 306.07 MT recycled in 2022. However, as the new processes have stricter raw materials requirements, much of the recycled NMP is now outsourced for reuse. Taiflex will invest funds by 2025 to implement purification system improvements, aiming at enhancing the recycling rate in the production line.

| Year | Category | Recycled Volume (MT) | Method of Disposal | Reuse Rate of Recycled Volume | |

|---|---|---|---|---|---|

| Outsourced for Reuse (MT) |

Recycled from Production Line (MT) |

||||

| 2021 | NMP | 379.35 | 60.35 | 319.21 | 84.15% |

| MEK | 124.16 | 54.95 | 69.21 | 55.74% | |

| 2022 | NMP | 306.07 | 19.25 | 286.82 | 93.71% |

| MEK | 153.76 | 70.13 | 83.63 | 54.39% | |

| 2023 | NMP | 353 | 126 | 227 | 64.31% |

| MEK | 148.2 | 57.1 | 91.1 | 61.47% | |

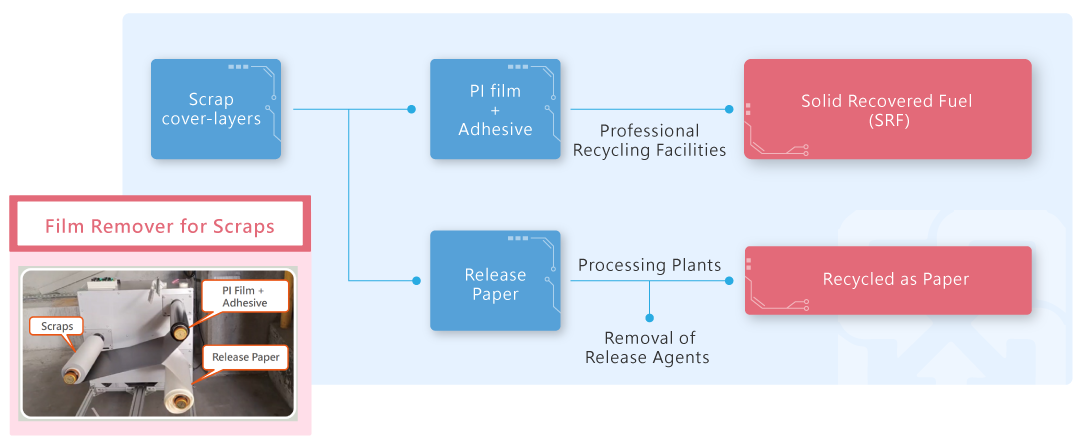

We insist on controlling the use of raw materials with the most optimal and feasible approaches, aiming to achieve a balance between environmental protection and economy with minimal waste and production costs. To reduce the heterogeneity of process scraps and improve the efficiency of waste recycling, the Manufacturing Center has developed in-house film removers in 2023 to peel off the release paper from the scrap cover-layers (PI film + adhesive + release paper). It is estimated that 50,000~70,000kg of release paper can be separately collected annually and recycled as papers. The remaining scraps (PI film+ adhesive) can then be further processed into solid recovered fuel (SRF), aligning with the government's promotion of the eco-concept - “waste to energy.”

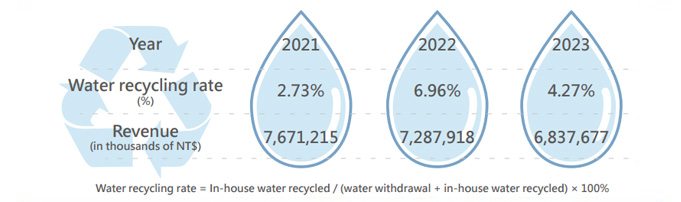

Taiflex is located in the Kaohsiung Qianzhen Technology Industrial Park, which has water supplied from the Fongshan Reservoir. According to the World Resources Institute's “Aqueduct Water Risk Atlas,” the risk of water resources in Taiwan is rated as low to medium.

Since we adopt dry process, production line is not where most of the water is consumed. As tap water is mainly used as cooling water for air conditioning, followed by employee daily usage and firefighting purposes, water resource management focuses on the promotion of domestic water conservation, including the recycling of RO and wastewater from drinking fountains as cooling water for air conditioning, dual flush toilet, recycling of rainwater from the roof and condensed water from air conditioning system for watering plants, and adjustments on the conductivity of water discharged from the air conditioning systems. Please refer to Appendix I ESG Information - Environmental Data of this report for detailed information on water consumption in 2023.

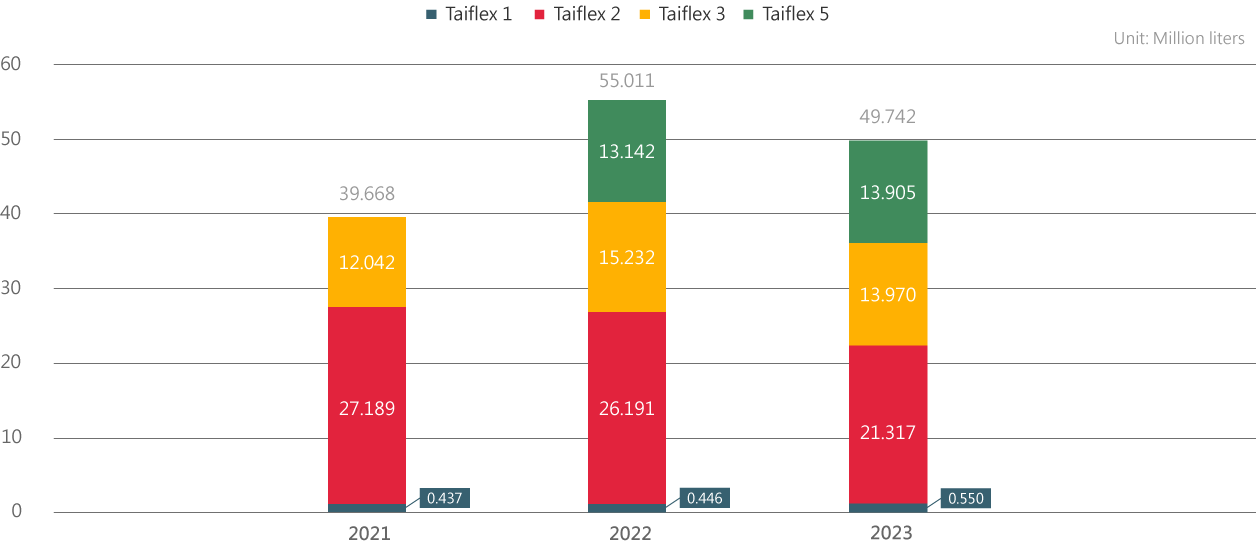

| Year | 2021 | 2022 | 2023 |

|---|---|---|---|

| Water withdrawal (million liters) | 86.210 | 91.550 | 89.830 |

| Water discharge (million liters) | 39.670 | 55.010 | 49.740 |

| Water consumption (million liters) | 46.540 | 36.540 | 33.200 |

| In-house water recycled (million liters) | 2.420 | 6.850 | 4.010 |

| Water recycling rate (%) | 2.730 | 6.960 | 4.270 |

| Revenue (in thousands of NT$) | 7,671,215 | 7,287,918 | 6,837,677 |

| Water use intensity (million liters / thousands of NT$) | 0.000011 | 0.000013 | 0.000013 |

Effluents from operation are mostly wastewater discharged from the cooling tower of factories and water used for domestic purposes, e.g., wash up or kitchen waste cleaning. Since they are discharged to sewers of the park, they would not affect the biodiversity in the area.

Our etching laboratory in Taiflex 1 would discharge etching wastewater; thus, a wastewater treatment system was installed. The system is equipped with pH and flow meters connected to the central monitoring system for constant online monitoring to ensure the effluents discharged fully meet the standards set by the Processing Zone. Testing at the outfalls is conducted twice every year and we also carry out monthly self-testing. The results have not only met the discharge standards but also stayed far below the regulatory requirements. The Company has never been penalized by the competent authorities since operation. Please refer to Appendix I ESG Information - Environmental Data of this report for detailed information on effluents quality tests.

| Test Items | 2021 | 2022 | 2023 | |||

|---|---|---|---|---|---|---|

| Discharge Standard | Annual Average | Discharge Standard | Annual Average | Discharge Standard | Annual Average | |

| Copper | 3.000 | 0.670 | 3.000 | 0.210 | 3.000 | 0.210 |

| Suspended solids | 450.000 | 14.460 | 450.000 | 60.930 | 450.000 | 41.180 |

| Biochemical oxygen demand | 450.000 | 43.730 | 450.000 | 91.630 | 450.000 | 37.490 |

| Chemical oxygen demand | 600.000 | 98.400 | 600.000 | 76.550 | 600.000 | 72.060 |

| pH | 9.000 | 8.300 | 9.000 | 7.960 | 9.000 | 7.860 |

| Water temperature | 42.000 | 26.950 | 42.000 | 26.980 | 42.000 | 27.290 |

Our air pollution control facilities adopt regulatory-compliant technologies available and comply with the “Air Pollution Control Act” as well as the “Air Pollutant Emission Standards of Stationary Pollution Sources.” The air pollution control facilities of each factory operate 24 hours a day and 350 days a year. Furthermore, we would engage a third-party certification body to conduct tests on the emission concentration of various air pollutants annually. The results have shown that our emissions have complied with relevant standards and stayed far below the threshold. Please refer to Appendix I ESG Information - Environmental Data of this report for statistics from the air pollution tests.

| Test Items | 2021 | 2022 | 2023 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Emission (kg/hr) | Emission Standard (ppm) | Annual Average (ppm) | Emission (kg/hr) | Emission Standard (ppm) | Annual Average (ppm) | Emission (kg/hr) | Emission Standard (ppm) | Annual Average (ppm) | |

| VOCs | 3.35 | None | 220 | 2.96 | None | 257 | 1.75 | None | 146 |

| TSP | 0.01 | 100.00 | 0.40 | - | 100.00 | - | 0.02 | 100.00 | 1 |

| SOx | - | - | - | - | - | - | - | - | - |

| NOx | 0.44 | 150.00 | 10 | - | 150.00 | - | 0.83 | 150.00 | 24 |

As natural gas combustion generates NOx emissions, and the Company mainly uses natural gas as fuel for exhaust gas treatment equipment, apart from reducing the total amount of exhaust gases (organic solvents) to be treated through raw material recovery, we continually optimize related equipment. Following the introduction of zeolite rotor concentrator at Taiflex 3 in 2022, there was a 30% reduction in natural gas consumption by the RTO compared to the base year (2021). Additionally, the replacement of ceramic media within the RRTO at Taiflex 2 in 2023 lowered natural gas consumption by approximately 25% compared to the base year, and further minimized NOx emissions. Besides, some of refrigeration equipment within the factory still use R22 refrigerant, and we continue to use GHG emission rate to calculate its emission volume. We will opt for models using environmentally friendly refrigerant in the future and gradually replace these older models. The amount of R22 refrigerant emissions in 2023 were 0.0046 MT.

| ODS | 2021 | 2022 | 2023 |

|---|---|---|---|

| R22 refrigerant | 0.040 MT | 0.0046 MT | 0.0046 MT |

We have restated the refrigerant filling quantities for 2022 based on the verified GHG inventory data for the year.

Synthesis and coating are the key processes of Taiflex. The production of FCCL generates hazardous solvent waste, which is harmful to the environment if not properly handled. Thus, it is collected in 53-gallon steel drums by the synthesis, front-end and back-end departments, and then purified for reuse through the recovery facilities to effectively reduce the outsourced volume and the associated treatment costs as well as realize circular economy (please refer to 4.3.1 Source reduction for details).

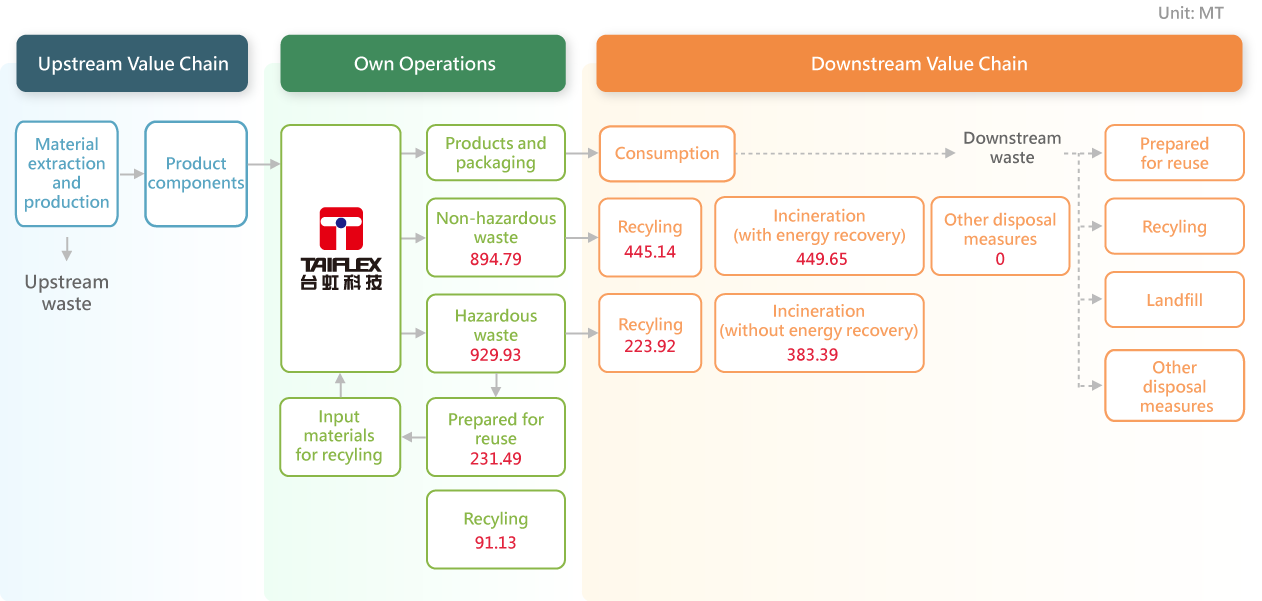

In addition to the reuse of NMP and MEK within the factories, we have started on-site adhesive washing due to the adoption of zero-waste policy in 2023. All other waste is treated off-site. Please refer to Appendix I ESG Information - Environmental Data of this report for detailed statistics.

We attach great importance to both on-site and off-site waste management. Operations such as terminal storage, removal, and reduction are centrally managed by the Environmental Sustainability Division. We continuously promote the concept of reuse internally and strive to recycle all reusable waste as well as improve resource efficiency to reduce environmental burden. Waste that cannot be reused are handled by third-party waste management professionals certified by the Environmental Protection Administration, and we conduct audits from time to time to ensure waste has been properly treated and to prevent environmental pollution due to negligence or violation of laws.

We stress the importance of waste recycling and detoxification with processes carried out in accordance with the Company's ISO 14001 Waste Disposal Management Standard (EI-PD-06), the “Waste Disposal Act” and the “Regulations Governing Determination of Reasonable Due Care Obligations of Enterprises Commissioning Waste Clearance.” Furthermore, we work toward the goals of localization, decentralization, and reclamation. The overall waste diversion rate (recycling rate) was 54% in 2023. With the addition of 25% from incineration with energy recovery, the rate was approximately 79%, and there was no leakage in 2023.