Safety Measures at Work Place

Realize OSH Policy and Goals

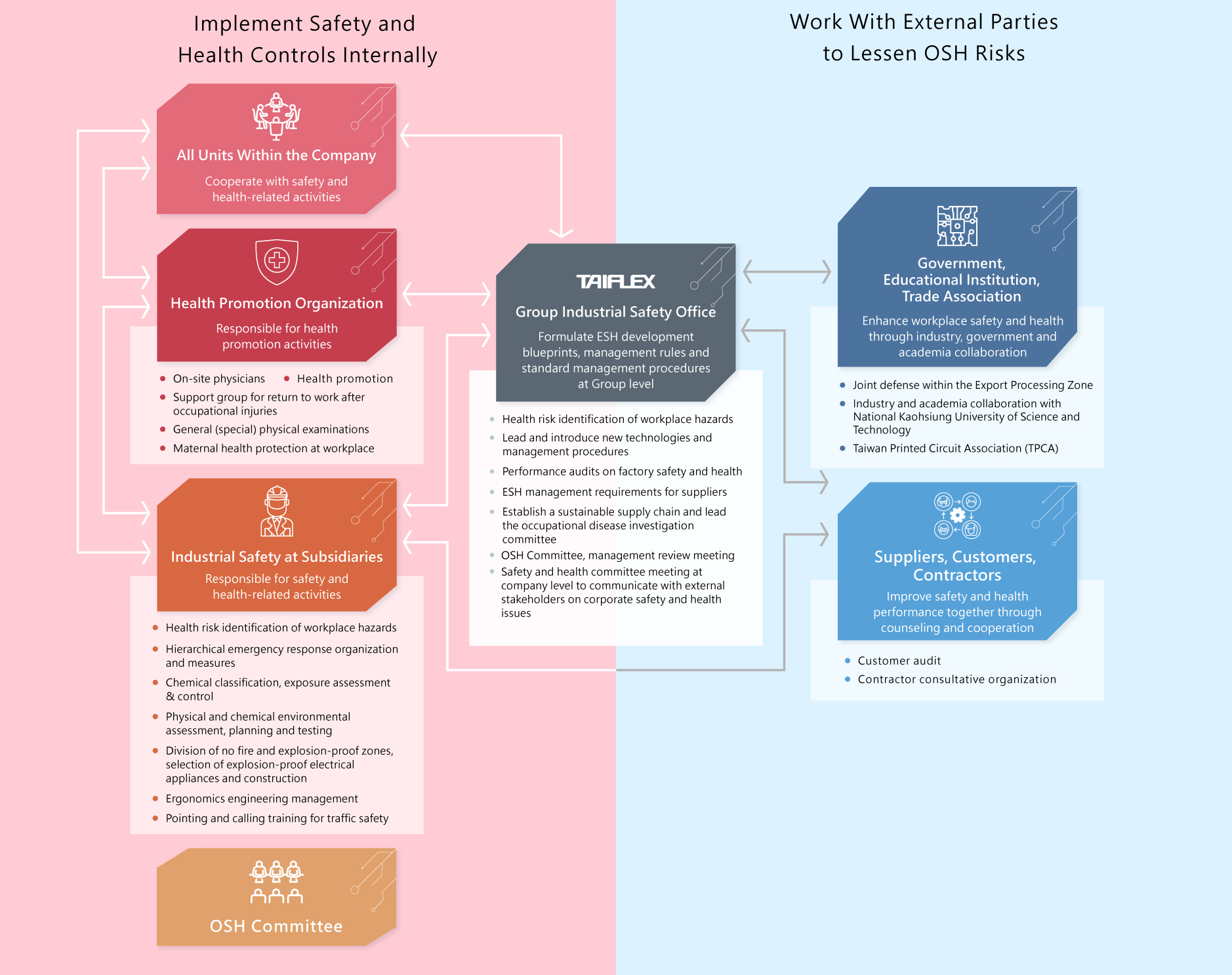

Taiflex obtained the ISO/CNS45001 certification for OSH management systems ahead of peers, aligning with global OSH management with our latest OSH management system. We proactively lower risk for regulatory compliance, meet the expectations of all stakeholders, create an OSH niche, and provide a harmonious production environment. We continue to carry out various safety and health measures pursuant to relevant policies and track progress to ensure safety culture and control risks.

| Year | Number of Attendees | Training Hours |

| 2024 | 2,407 | 1,953.5 |

| 2023 | 2,228 | 1,217.3 |

| 2022 | 2,560 | 2,094.5 |

| Year | Fatal Accidents | Disability Accidents |

| 2024 | Male:0 Female:0 | Male:5 Female:2 |

| 2023 | Male:0 Female:0 | Male:5 Female:0 |

| 2022 | Male:0 Female:0 | Male:7 Female:2 |